КАТО 100 (ОБОРУДВАНЕ ПОД НАЕМ)Hosokawa Alpine

AS Aeroplex

КАТО 100 (ОБОРУДВАНЕ ПОД НАЕМ)

Hosokawa Alpine

AS Aeroplex

Година на производство

2023

Състояние

Нов

Местоположение

Augsburg

Покажи снимките

Показване на карта

Данни за машината

- Описание на машината:

- КАТО 100 (ОБОРУДВАНЕ ПОД НАЕМ)

- Производител:

- Hosokawa Alpine

- Модел:

- AS Aeroplex

- Година на производство:

- 2023

- Състояние:

- нов

- функционалност:

- напълно функциониращ

Цена и локация

- Местоположение:

- Peter-Dörfler-Straße 13-25, 86199 Augsburg, DE

- наем:

- възможно е

Позвънете

Детайли за офертата

- Обява №:

- A14383945

- Последна актуализация:

- на 10.02.2025

Описание

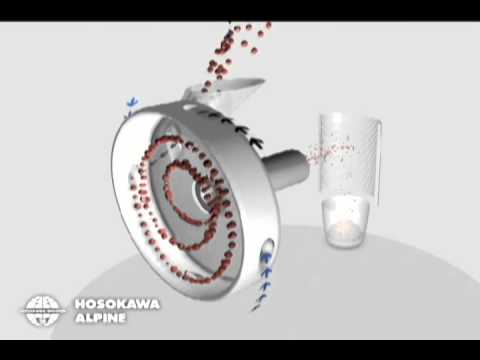

Hosokawa Alpine AS 100 Aeroplex Rental System

The Hosokawa Alpine Aeroplex AS spiral jet mill is a simple jet micronizer without a dynamic classifier (unlike the Hosokawa Alpine AFG), enabling ultra-fine micronization, achieving particle sizes between 10 and 150µm for various products. It is mainly used for processing dry and non-abrasive materials with a hardness of up to 3 Mohs, although some models can be fitted with abrasion-resistant inserts. This granulator’s design, with no moving parts (thus, no bearings or lubricants), makes it ideal for use in pharmaceutical or food applications, as well as in the chemical industry, for example.

Grinding is carried out inside the milling chamber, where the product is accelerated by compressed gas injected through the grinding nozzles, causing particles to collide with each other, breaking them down and thus reducing their size. Once fine enough, the fine particles are drawn towards the central output of the mill, acting as a static classifier, though without as precise top particle cut-off as the AFG (which is equipped with a classifier wheel). The next stage is typically product discharge from the system via a cyclone or air filter. Thanks to the amount of air required, the temperature increase is considerably lower compared to other milling and grinding technologies. The particle size distribution of the final product can be easily adjusted by changing various parameters, such as the gas pressure in the grinding nozzles, the product feed injector, air volume, feeding rate, etc.

A HOSOKAWA ALPINE Originals machine

- Refurbished by the original manufacturer

- Exclusive use of original components

- Original manufacturer's warranty

- Guaranteed spare parts supply by the manufacturer

Csdpfx Afjq A T Ilelerh

- Shorter delivery times

- Before delivery, the machine is inspected, all wearing parts are checked and replaced if necessary, and the machine is customized to your specific requirements

- Option to provide all required peripherals or to adapt to your existing production plant

- We are also interested in repurchasing unused HOSOKAWA ALPINE equipment

Technical details:

- Stainless steel construction, pharmaceutical design

- No explosion protection (NPSR), option for operation under inert gas atmosphere (N2)

- Batch operation, typically a few grams (depending on material)

Scope of supply:

- Complete small-scale system, including feeding channel, AS spiral jet mill, manual controls, and filter

Обявата е преведена автоматично и може да има някои грешки в превода.

The Hosokawa Alpine Aeroplex AS spiral jet mill is a simple jet micronizer without a dynamic classifier (unlike the Hosokawa Alpine AFG), enabling ultra-fine micronization, achieving particle sizes between 10 and 150µm for various products. It is mainly used for processing dry and non-abrasive materials with a hardness of up to 3 Mohs, although some models can be fitted with abrasion-resistant inserts. This granulator’s design, with no moving parts (thus, no bearings or lubricants), makes it ideal for use in pharmaceutical or food applications, as well as in the chemical industry, for example.

Grinding is carried out inside the milling chamber, where the product is accelerated by compressed gas injected through the grinding nozzles, causing particles to collide with each other, breaking them down and thus reducing their size. Once fine enough, the fine particles are drawn towards the central output of the mill, acting as a static classifier, though without as precise top particle cut-off as the AFG (which is equipped with a classifier wheel). The next stage is typically product discharge from the system via a cyclone or air filter. Thanks to the amount of air required, the temperature increase is considerably lower compared to other milling and grinding technologies. The particle size distribution of the final product can be easily adjusted by changing various parameters, such as the gas pressure in the grinding nozzles, the product feed injector, air volume, feeding rate, etc.

A HOSOKAWA ALPINE Originals machine

- Refurbished by the original manufacturer

- Exclusive use of original components

- Original manufacturer's warranty

- Guaranteed spare parts supply by the manufacturer

Csdpfx Afjq A T Ilelerh

- Shorter delivery times

- Before delivery, the machine is inspected, all wearing parts are checked and replaced if necessary, and the machine is customized to your specific requirements

- Option to provide all required peripherals or to adapt to your existing production plant

- We are also interested in repurchasing unused HOSOKAWA ALPINE equipment

Technical details:

- Stainless steel construction, pharmaceutical design

- No explosion protection (NPSR), option for operation under inert gas atmosphere (N2)

- Batch operation, typically a few grams (depending on material)

Scope of supply:

- Complete small-scale system, including feeding channel, AS spiral jet mill, manual controls, and filter

Обявата е преведена автоматично и може да има някои грешки в превода.

Доставчик

Забележка: Регистрирайте се безплатно или влезте, за да получите достъп до цялата информация.

Регистриран от: 2019

Изпратете запитване

Телефон & Факс

+49 821 2... обяви

Вашата обява беше успешно изтрита

Възникна грешка